Table of contents

Chapter 1: What is the most common flatbed trailer?

Chapter 2: What are the benefits of a flatbed trailer?

Chapter 3: What is the load capacity of a flatbed trailer?

Chapter 4: Package and delivery of flatbed semi trailer

Chaper 5: Comparison between TITAN and CIMC flatbed trailer

Chapter 6: What is the difference between flatbed trailer and skeletal trailer?

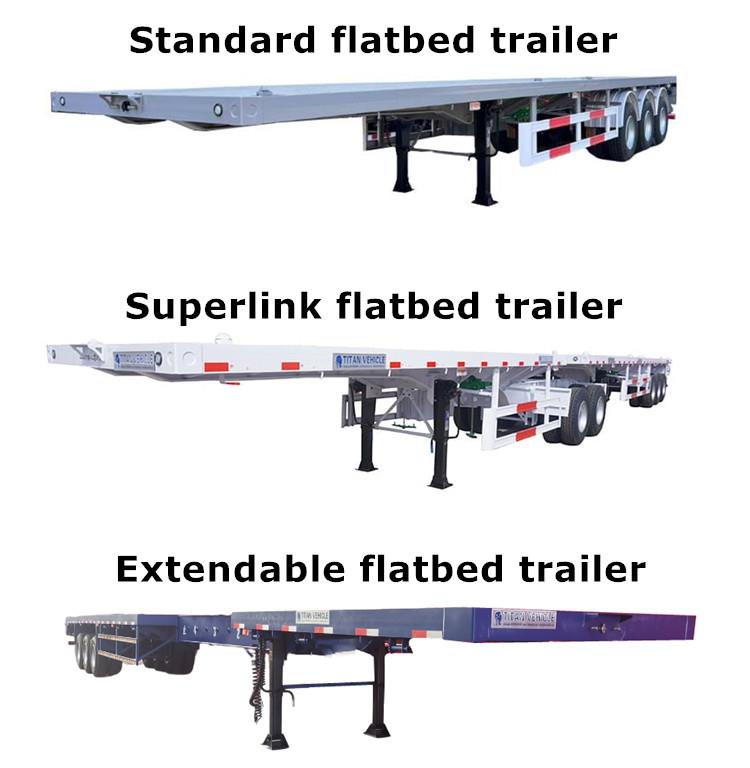

The most common type of flatbed trailer is the standard flatbed trailer. It is a versatile trailer with a flat, open platform that allows for easy loading and unloading of various types of cargo. The absence of sides and roof allows for easy loading and unloading from the sides or overhead using cranes or forklifts. Flatbed trailers are commonly used to transport items such as construction materials, machinery, vehicles, and other oversized or irregularly shaped loads.

By simple definition, this is a long flat platform of either 20ft, 40ft, 48ft or 53ft length. TITAN flatbed trailer in Namibia is usually used to transport 20ft or 40ft containers, they are mainly used for container transportation supporting ships, ports, shipping lanes, highways, transit stations, bridges, tunnels, and multimodal transport.

Other types of flatbed trailers:

1. Flatbed trailer with drop side

The flatbed trailer with drop side also called side wall trailer. This side wall cargo trailer use to load a wide range of products and materials, like sand, bags, poultry etc. Also the some bulk cargo, very widely used in the transportation industry. Suitable for the mid/long distance transportation of the mid/heavy duty and bulk cargo. The high side tri axle cargo trailer can be added with a container turn lock to transport the container.

2. Extendable flatbed trailer

An extendable flatbed trailer is designed for hauling particularly long cargo, it can be adjusted in length to accommodate oversized loads. It typically has telescopic sections that can be extended or retracted, providing flexibility for carrying extra-long cargo.

3. Tipper flatbed trailer

The striking feature with the tipper flatbed trailer is a mechanism that makes it easy to unload the container.There are apparatus added as modifications to the conventional tri axle trailer models further simplifying the process of offloading cargo from the container.

The hydraulic system mounted on the upper platform facilitates the offloading process causing the container to tilt upwards to offload cargo. Tipper flatbed trailer is definitely one of the safest means of offloading shipping containers. The tipper flatbed trailer comes with a hydraulic lifting cylinder that contracts longitudinally to facilitate loading and on the other hand, they extend in an outward manner to enhance the offloading process.

4. Superlink flatbed trailer

A superlink flatbed trailer consists of two separate flatbed trailers coupled together using a fifth wheel connection and a dolly.

The primary characteristic of a superlink flatbed trailer is its ability to carry a larger volume of cargo compared to a standard flatbed trailer. The coupling of two trailers creates an extended platform with multiple levels or decks for cargo placement. This configuration effectively doubles the load capacity of a single flatbed trailer.

5. Curtain side flatbed trailer

Also known as a soft-sided flatbed trailer, a curtain sider has a flatbed deck and a curtain-like soft cover on the sides. The curtains can be slid open to allow for easy loading and unloading of cargo while providing some protection from the elements.

There are several benefits of using a flatbed trailer for transporting cargo:

1. Versatility: Flatbed trailer in Namibia is versatile and can be used to transport a wide range of cargo, including oversized or irregularly shaped loads that cannot fit inside an enclosed trailer.

2. Easy loading and unloading: The open design of a flatbed trailer makes it easy to load and unload cargo from the sides or overhead using cranes or forklifts.

3. Increased capacity: Flatbed trailers have a higher weight capacity compared to enclosed trailers, which means they can carry heavier loads.

4. Cost-effective: Flatbed trailers are often more cost-effective than other types of trailers, especially for transporting large or bulky cargo.

5. Reduced risk of damage: The open design of a flatbed trailer in Namibia reduces the risk of damage to the cargo during loading and unloading.

6. Improved visibility: Flatbed trailers provide better visibility for drivers, which can improve safety on the road.

Overall, flatbed trailers are a popular choice for transporting a wide range of cargo due to their versatility, ease of use, and cost-effectiveness.

The load capacity of a flatbed trailer can vary depending on several factors, including the size and weight of the trailer, the number of axles, and the weight distribution of the cargo. TITAN can customize the load for you according to your needs, and different configurations have different prices. Usually the load capacity of a flatbed trailer is 50-80 tons.

TITAN flatbed trailer in Namibia adopts high strength steel material to manufacture the flatbed trailer, it can make the flatbed trailer have a higher loading capacity and a longer service life

TITAN tri axle flatbed trailer uses automatic arc-submerging welding method to weld the main beam, so the main beam is more stronger and more durable. The whole complete main beam can improve the loading capacity by 20%

The thickness of the side beam we made is 160mm, 100mm channel for through beam, and all of the through beam are supported by the Inclined support frame, and the distance of these frame no more than 500mm, which can ensure the flatbed trailer not easy to deform.

The floor plate of flatbed trailer in Namibia is the 3 mm and it’s diamond plate, It is thicker than the 2.5mm or 2mm floor plate of other factories. The floor plate is strong and durable, and is not easy to deform.

Flatbed trailers in Namibia are usually transported by sea, generally in four ways: container, ro-ro ship, bus deck and bulk cargo ship. TITAN's sales manager will recommend the most appropriate and cheapest transportation method to customers based on their needs and specific circumstances. Among them, flatbed trailer usually delivery by container and Ro-Ro Ship, velow I will introduce in detail the advantages of these two modes of transportation.

1. By container: Containers provide good cargo protection. The flatbed trailer is enclosed in the container, which can effectively prevent damage to the trailer from external factors, such as bad weather, seawater immersion, etc. And containers can be securely sealed before loading to ensure that the goods are not subject to the risk of unauthorized opening or tampering during transportation. This helps prevent theft and illegal activity.

In order to load the flatbed trailer into the container, we will disassemble the flatbed trailer to a certain extent, and the customer will need to install it by himself after arrival.

2. By ro-ro ship: Ro-Ro ship is particularly suitable for large volumes of vehicles or oversized cargo, making it more efficient compared to other methods. With Ro-Ro shipping, flatbed trailer is securely stowed within the vessel, minimizing the risk of damage during transport. Flatbed trailer typically lashed or secured in designated spaces, ensuring stability and protection throughout the journey.

We will spray a thick layer of wax on the flatbed trailer to reduce the damage caused by seawater erosion of the flatbed trailer during transportation. After the trailer is sprayed with wax, we will wrap the body with rain cloth, which is also to reduce the erosion of the flatbed semi trailer by seawater during transportation.

When it comes to comparing TITAN and CIMC flatbed trailers, both brands have their strengths and features that make them popular choices in the vehicle industry. Let's take a closer look:

1. Quality and Durability:

Both TITAN and CIMC are well-known for manufacturing high-quality flatbed trailers that are built to withstand tough hauling conditions. Their trailers are designed with sturdy materials and construction to ensure longevity and durability.

Overall, I would say both brands offer reliable and robust flatbed trailers that can handle heavy loads and rough terrains.

2. Design and Customization:

TITAN and CIMC provide options for customization to meet specific hauling requirements. They offer various trailer lengths, widths, and configurations, allowing customers to tailor the trailer to their needs.

With both brands, you can generally expect flexibility in trailer design and the ability to choose additional features or accessories to optimize your hauling operations.

3. Technology and Innovation:

TITAN continues to innovate appearance design and improve product quality. In some aspects, TITAN flatbed trailer has surpassed CIMC and achieved industry-leading quality.

4. Price and Availability:

Price points and availability can vary depending on factors such as your location and specific trailer requirements.

Welcome to contact us to get detailed quotation, we provide TITAN and CIMC brand flatbed trailer and can meet all your customized requirements.

A flatbed trailer is a type of trailer with a flat, open platform for carrying cargo. It typically has no sides or roof, allowing for easy loading and unloading of various types of cargo, including large and bulky items. The cargo is typically secured using straps or chains.

Advantages of a flatbed trailer:

1. Versatility: Flatbed trailers can transport a wide range of cargo, including oversized and irregularly shaped items. Their open design allows for flexibility in loading and unloading different types of goods.

2. Easy Loading and Unloading: With no sides or roof, flatbed trailers provide easy access for loading and unloading cargo. This can save time and effort compared to trailers with enclosed bodies.

3. Accessibility: The open nature of flatbed trailers allows for quick and convenient access to the cargo from all sides. This makes it easier to secure the load and perform necessary inspections during transit.

Disadvantages of flatbed trailers:

1. Limited protection: Flatbed trailers have an open design with no sides or roof, which means that cargo is fully exposed to the elements. This can be a disadvantage when transporting goods that are sensitive to weather conditions, such as perishable items or delicate equipment.

2. Load securing challenges: Since there are no walls or sides to contain the cargo, securing the load on a flatbed trailer can be more challenging compared to enclosed trailers. Cargo must be properly secured with straps, chains, or other devices to prevent shifting or damage during transport.

On the other hand, a skeletal trailer, also known as a skeleton trailer or chassis trailer, is a type of trailer that consists of a lightweight frame structure with minimal or no bodywork. It is designed to carry shipping containers, with the container being secured to the trailer using twist locks at the corners. Skeletal trailers are commonly used for transportation and intermodal operations, as they provide a secure and efficient way to transport containers.

Advantages of a skeletal trailer:

1. Container Transport: Skeletal trailers are specifically designed for transporting shipping containers. They have twist locks or other securing mechanisms that ensure the containers are securely attached to the trailer chassis, making them ideal for intermodal operations and containerized freight.

2. Lightweight: Skeletal trailers are typically lightweight compared to other types of trailers, which can contribute to better fuel efficiency and increased payload capacity. The lighter weight also allows for easier maneuverability and reduces wear and tear on the vehicle.

3. Modular Design: Skeletal trailers often have a modular design, which means they can be configured for different container sizes, such as 20-foot, 40-foot, or 45-foot containers. This flexibility makes them compatible with various container types and enables efficient handling and transport within the logistics industry.

Disadvantages of skeletal trailers:

1. Dependency on containers: Skeletal trailers are specifically designed to transport containers, so they may not be as versatile for carrying other types of cargo. If the transportation needs involve a variety of load types or dimensions, a different trailer configuration may be more suitable.

2. Handling and maneuverability challenges: Skeletal trailers can be more challenging to handle and maneuver compared to other trailer types. The weight distribution and position of the container on the trailer can affect stability and maneuverability, requiring skilled drivers and more cautious towing practices.

In summary, while both flatbed and skeletal trailers are used for transporting cargo, flatbed trailers have an open platform for carrying various types of cargo, whereas skeletal trailers are specifically designed to carry shipping containers.